The oil filter, as its name implies, plays a role in filtering and cleaning. If you just think so, it is far from enough. The quality of the filter is directly related to the power output performance of the engine, the durability of the engine and the fuel consumption rate. The harmful substances (metal abrasive particles, dust, sludge, etc.) produced by the engine during operation will affect the engine. In order to make the oil flow in the lubricating system unobstructed, the oil filter prevents impurities from scratching and pulling the surface of the parts. Before rubbing the surface, it must be strictly filtered.

However, the oil will clean and dissolve the generated impurities and flow back to the oil pan. After being filtered again, the oil filter works to filter out the harmful impurities in the oil from the oil pan, and the filtered oil is supplied to the crankshaft. , connecting rod, camshaft, supercharger, piston ring and other moving pairs, play the role of lubrication, cooling and cleaning, thereby prolonging the life of parts. Therefore, it is recommended to replace the oil filter together with the oil maintenance.

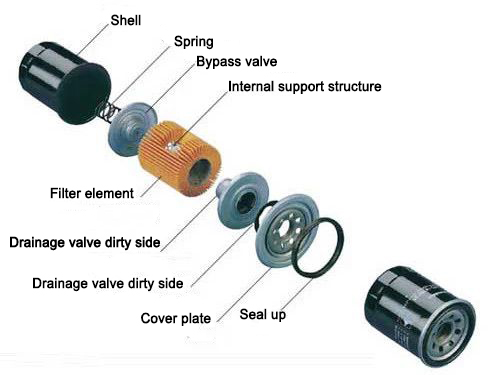

In general, the engine lubrication system will be equipped with several filters with different capacities – a collector, a coarse filter and a fine filter, which are respectively connected in parallel or in series in the main oil passage of the engine. The oil filter structure mainly includes filter paper, rubber sealing ring, backflow suppression valve, overflow valve, etc.

Bypass valve: also known as overflow valve, when the external temperature drops to a certain value or when the oil filter exceeds the normal service life, the overflow valve will be opened under special pressure, allowing the unfiltered oil to flow directly. into the engine.

Nevertheless, impurities in the oil will enter the engine together, but the damage is much less than the damage caused by no oil in the engine. Therefore, the relief valve is the key to protect the engine in an emergency.

Filter paper: It is the key to the oil filter, and the requirements are particularly high, mainly because the temperature of the oil varies from 0 to 300 degrees. Under the severe temperature change, the concentration of the oil also changes accordingly, which will affect the oil. Filter traffic. The filter paper of a high-quality oil filter should be able to filter impurities under severe temperature changes, while ensuring sufficient flow.

Check valve: Also known as the backflow suppression valve, it prevents the oil filter from drying out when the engine is turned off; when the engine is re-ignited, it immediately generates pressure to supply oil to lubricate the engine.

Sealing rubber ring: It is a sealing ring synthesized with special rubber to ensure 100% oil leakage.

As a common consumable for trucks, filtration technology has been continuously innovated and the structure has been optimized, but no matter how good the product structure is, it is still inseparable from the reasonable maintenance of drivers and friends. Observe and pay more attention in the daily driving process, and the maintenance is due. In this way, the safety and efficiency of the truck can be ensured, and the engine is durable, thereby reducing the comprehensive transportation cost of drivers and friends.

From the anatomy of GHL oil filter, the texture is clear, the paper material is good, the density is uniform, the pressure resistance is strong, and the oil is good. .

Post time: May-11-2022