Many friends may know what is a construction machinery filter, but how much do you know about the misunderstanding of the use of construction machinery filters?

Myth 1: “As long as the filter is cheap, it can be installed on the engine perfectly.”

Many domestic filter manufacturers only simply copy and imitate the geometric dimensions and appearance of the original parts, and do not pay attention to the engineering standards that the filter should meet. The filter is designed to protect the engine system. If the performance of the filter cannot meet the technical requirements and the filtering effect is lost, the performance of the engine will be significantly reduced and the service life of the engine will be shortened.

Myth 2: “If you don’t have to change the filter frequently, this filter is definitely good.”

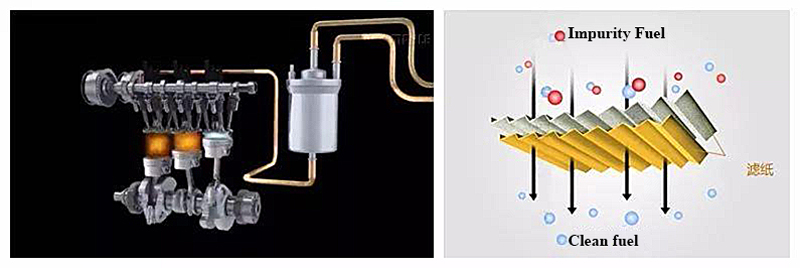

The function of the filter is to filter out the dust and impurities in the air, oil, fuel, and keep these impurities away from the engine, thereby protecting the engine system. High-quality high-efficiency filters can capture and filter more impurities than low-efficiency filters. If the dust holding capacity of the two filters is the same, it is obvious that the replacement frequency of the high-quality high-efficiency filter will be higher.

Most of the low-quality filters sold on the market have filter short circuits (impurities enter the engine system directly without filtering). The reason for the short circuit is the perforation of the filter paper, the end and end of the filter paper are not bonded or not firmly bonded, and the filter paper and the end cover are sticky. Can’t connect well. Such filters have no filtering function and therefore do not need to be replaced.

Myth 3: “The filter used did not cause any trouble. There is no need to spend more money to buy a high-quality filter.”

The impact of low-efficiency and low-quality filters on the engine may or may not be seen immediately. The engine seems to be operating normally, but harmful impurities may have entered the engine system long ago and have begun to cause corrosion, rust, and wear of engine parts.

These damages are hidden and will explode when the damage accumulates to a certain extent, so that a large amount of money has to be spent on repairing the engine.

Myth 4: “The engine is worn out. After the warranty period, there is no need to use high-quality high-quality filters.”

Old engines are more prone to wear and cause cylinder pull. Therefore, old engines need high-quality filters to stabilize the escalating wear and tear and maintain engine performance. Otherwise, you will not need to spend a lot of money on repairs or scrap the engine in advance.

Post time: Nov-12-2021