The oil filter acts as a consumable part on the truck and is replaced every time the oil is changed. why? What is the oil filter?

Let’s take a look at the main types of typical engine oil pollution:

1. Organic pollutants (commonly known as “sludge”) are mainly derived from unsealed, unburned hydrocarbons, soot, moisture, and dye dilutions, accounting for 75% of the oil filter contaminants.

2. Inorganic pollutants (dust) are mainly derived from dirt and wear material products, accounting for 25% of the oil filter pollutants.

3. Harmful acidic substances are mainly derived from by-products, chemical consumption of oils, etc., which account for very few pollutants in the oil filter.

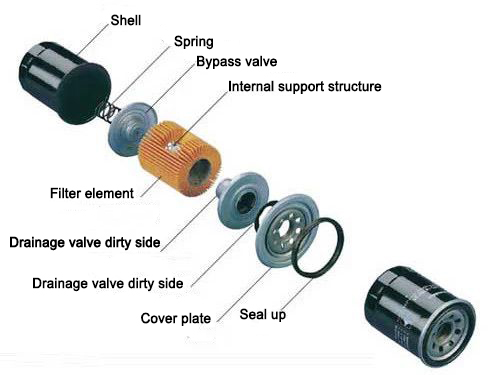

Next, let’s look at how the structure filters these contaminants:

There are replaceable, spin-on, centrifugal; according to the layout in the system can be divided into full-flow, split-flow. In general engine lubrication systems are equipped with several filters with different filtration capabilities – filter, strainer and fine filter, respectively, in parallel or in series in the main oil gallery of the engine. (The full-flow filter is connected in series with the main oil passage. When the engine is working, the lubricating oil is completely filtered by the filter; the shunt filter is connected in parallel with it). The coarse filter is connected in series in the main oil passage and is full-flow type; the fine filter is connected in parallel in the main oil passage.

The most widely used oil filter structures now include filter paper, rubber seals, backflow suppression valves, bypass valves, and more.

Filter paper: It is the key to the oil filter. The requirements are particularly high, mainly because the temperature change of the oil varies from 0 to 300 degrees. Under the sudden temperature change, the oil concentration also changes accordingly, which will affect the oil. Filter traffic. The filter paper of a high-quality oil filter should be able to filter impurities under severe temperature changes while ensuring sufficient flow.

Rubber sealing ring: Sealing ring made of special rubber should ensure 100% oil leakage.

Backflow suppression valve: Also known as a check valve, it prevents the oil filter from drying out when the engine is turned off; when the engine is re-ignited, it immediately generates pressure to supply oil to lubricate the engine.

Bypass valve: When the external temperature drops to a certain value or when the oil filter exceeds the normal service life, the bypass valve opens under special pressure, allowing unfiltered oil to flow directly into the engine. Despite this, the impurities in the oil will enter the engine together, but the damage is much smaller than the damage caused by the lack of oil in the engine. Therefore, the bypass valve is the key to protecting the engine in an emergency.

With the development of technology, the structure of the oil filter has also changed. From the past, the replaceable oil filter has developed into the current mainstream rotary type, and the filter paper has also developed from the cellulose material into the mainstream composite material, which is continuously optimized and upgraded. The oil filter structure not only serves the engine better, but also meets the needs of users.

Post time: Apr-22-2019