We all know that a diesel engine needs to mix air and diesel efficiently to achieve work. If the inhaled air contains dust and impurities, it will directly affect the combustion efficiency of the engine, and even aggravate the wear of the parts. The engine “cylinder” phenomenon occurs, so an air filter appears. .

Let’s look at the classification of air filters: air filters generally have two types, dry and wet. Dry air filters are filters that separate impurities in the air through a dry filter element; about wet air filters, agricultural machinery Most of the air filters used above are oil-bath air filters (a few of them are oil-immersed). The oil-bath type means that the sucked air containing dust particles is introduced into the oil pool to remove most of the dust, and then the air with oil mist is removed. When it flows upward through a filter screen made of metal wire, it is further filtered, and the oil droplets and the blocked dust particles return to the oil pool together. The following picture shows the oil bath air filter(left) and dry air filter (right) used on high-horsepower tractors:

According to the agricultural machinery guide market research, engine failures caused by poor air filtration accounted for about 18% of total engine failures in 2019. Indeed, many engine failures are related to improper use and maintenance of air filters. Let’s talk today. How to maintain the air filter used on tractors and harvesters to reduce the engine failure rate caused by this?

In the past, most of the air filters used on tractors were oil-bath air filters, but nowadays, on high-horsepower tractors, including harvesters, wheat harvesters and other agricultural machinery, more and more dry air filters are used. How effective is the air filter? Or is the oil-bath air filter better? According to the experimental data and market usage investigation, the filtration effect of dry air filter is better. However, it is found in the market that many tractor drivers and harvester drivers have objections to the use of dry air filter. The filtering effect of the air filter is not as good as the oil bath type. In fact, this is a kind of prejudice.

In actual use, dry air filters have many advantages compared with oil bath air filters:

First, the filtration efficiency of dry air filters can reach more than 99.5%, and the dust transmission rate of dry air filters is only 0.1%—0.3%. The air inhaled by the engine is cleaner, which may effectively extend the life of the engine. The filtration efficiency of the filter is only about 98%, which is significantly lower than that of the dry air filter;

Second, the dry air filter has a more compact structure and a more convenient layout;

Third, during maintenance, since the dry air filter does not require oil consumption, it is more environmentally friendly, more convenient to maintain, and takes less time to maintain, and it can also save a lot of auxiliary consumables such as cotton yarn and diesel for cleaning;

Fourth, the dry air filter is lighter in weight and lower in overall cost.

In engine use, the air filter is very important to the engine. 90% of the external pollution to the engine comes from air pollution. Effectively filter the air entering the engine to allow clean air to enter the engine cylinder to ensure that the engine is normal. It is a necessary condition for work. The air that has not been effectively filtered into the cylinder will cause rapid wear of the engine cylinder, causing problems such as early engine wear, insufficient power, black smoke, and even cylinder pulling. The correct use and maintenance of the air filter is directly related to the engine The service life of the air filter, so the effective filtering effect of the air filter must always be maintained during use.

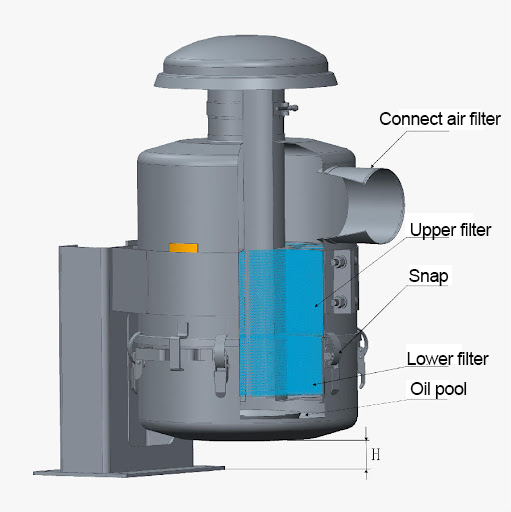

When the oil-bath air filter is working, the incoming air will generally go through three stages: inertial filtration, oil-bath filtration, and filter filtration.The main components of the oil bath air filter air filter include: dust cup, center tube, oil pool, upper and lower metal filter screens, etc. The maintenance must pay attention to the following aspects:

First, clean the lower chamber oil sump and the metal filter screens of the upper and lower chambers regularly, and replace with new engine oil. The brand of the new engine oil should be the same as that of the engine oil pan.

Second, the oil level in the oil sump of the lower cavity should be moderate, just add it to the arrow mark of the oil sump. When the oil level is too low, the amount of oil is insufficient, and the air filtration effect is poor; when the oil level is too high, the amount of oil is too much, and the engine is easy to be sucked into the cylinder and burned when the engine is working. “The accident.

Third, the dust in the dust collection cup should be cleaned regularly and timely. When working in a dusty and harsh environment, it should be cleaned once every shift, and the oil level of the oil pool and the cleanliness of the oil should be checked. When the oil level is too low, Refill in time, clean and replace with new oil in time when the oil is too dirty.

The picture below is the structure of the dry air filter:

Dry air filter is mainly composed of outer filter element, inner filter element, and sealing gasket. The maintenance of dry air filter should pay attention to the following aspects:

First, the working environment of tractors and harvesters is relatively harsh. When working in a dusty environment, the air filter must be checked once every shift (8-10 hours), and the inner cavity of the air filter, the air duct, and the dust must be cleaned in time. Special attention should be paid to the dust in the bag, do not think that the air duct is useless and throw it away.

Second, when the dry air filter is maintained, only the vibration method, the soft brush method (brushing along the creases) or the compressed air blowback method can be used to clean the dust and other debris attached to the surface or inside of the filter element. For the main filter element, lightly tap or use a brush to remove the dust on the surface of the main filter element, and then use compressed air to blow from the inside of the filter element, remember! It must be blown from the inside of the filter element, but not from inside. The compressed air pressure is 0.15-0.40MPa. Note that the air pressure cannot be too high (it is easy to blow and damage the filter when it is too high) or too low (when it is too low) The filter element cannot be cleaned). For the inner filter element (safety filter element), you can only pat it or use a soft brush to remove dust, not using compressed air.

Third, when cleaning and cleaning the air filter, the filter element of the dry air filter must not be cleaned in oil or water. Once the filter element is cleaned with water or oil, it will fail and may cause a speed accident.

Fourth, after cleaning and installing the air filter, pay attention to check whether the seal is defective. After the filter element is installed, rotate it to make it securely in place. When tightening, ensure a safe seal. Do not use excessive force to damage the air filter end cover and cause air. Short circuit, but also pay attention to the direction of the dust bag mouth must be downward.

Fifth, dust is the biggest killer of diesel engines. When you find that the filter element is severely deformed, the filter paper is damaged, the filter hole is severely clogged, or the filter is too dirty, you should immediately replace the new filter element, remember.

Sixth, we must purchase qualified filter elements to avoid the use of inferior filter elements, improper maintenance and insufficient power of the diesel engine, and early wear of cylinder liners and piston rings.

All GHL products are produced in accordance with TS16949 standard,and our company has the ISO 9001 certification, you can trust us.

The above is all the sharing for today, I hope to help everyone!

Post time: Aug-20-2021