1. Oil filter-composition and characteristics

Oil filter, also known as “oil grid”. Used to remove impurities such as dust, metal particles, carbon deposits, soot particles and colloids in engine oil to protect the engine.

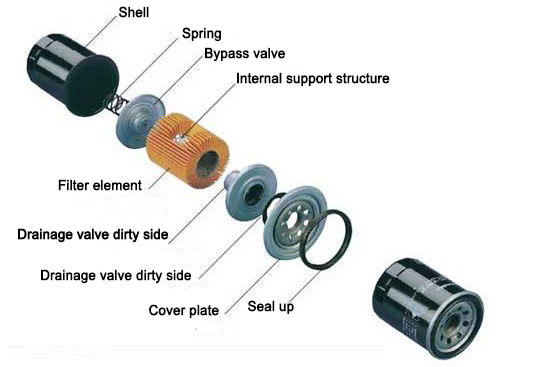

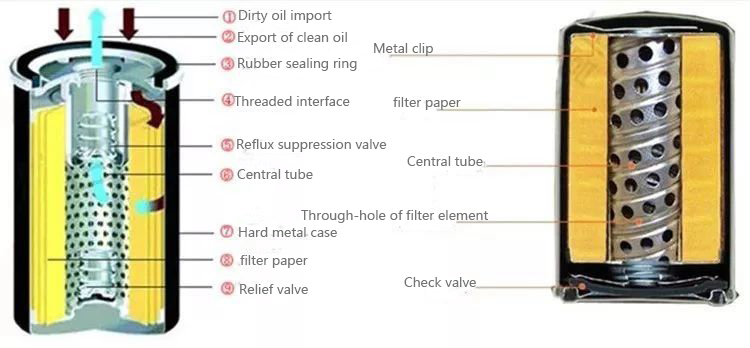

It is composed of filter paper, rubber sealing ring, backflow suppression valve and overflow valve.

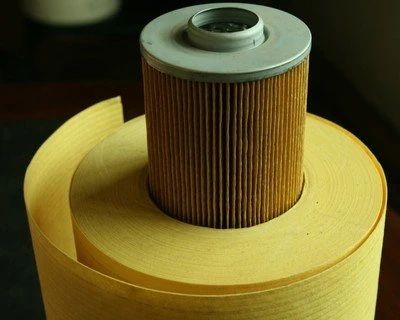

1. Filter paper:

The oil filter requires higher filter paper than the air filter, mainly because the temperature of the oil varies from 0 to 300 degrees. The filter paper of the high-quality oil filter must be able to filter impurities under drastic temperature changes, while Also ensure sufficient flow.

Note: Inferior and cheap filter paper is mostly made of cotton pulp paper. The filtration effect is extremely poor. It is easier to decompose and dissolve into the engine oil, block the oil passage, accelerate the deterioration of the engine oil, and even accelerate the engine damage.

2. Rubber sealing ring:

The high-quality oil filter seal ring is made of special rubber to ensure 100% oil-free.

Note: A good oil filter will not leak oil under normal installation conditions. There are many problems with poor quality and low oil leakage.

3. Backflow suppression valve:

Only available in high-quality oil filters. When the engine is turned off, it prevents the oil filter from drying out; when the engine is re-ignited, it immediately generates pressure to supply oil to lubricate the engine. (Also called check valve)

Note: Maintain the pressure of the engine lubrication system to reduce wear. Inferior and low-quality oil filters have no check valve, which accelerates engine wear when starting.

4. Overflow valve:

Only available in high-quality oil filters. When the external temperature drops to a certain value or when the oil filter exceeds the normal service life, the overflow valve will open under special pressure to allow unfiltered oil to flow directly into the engine to lubricate the friction components-not Filtered impurities increase engine wear. Therefore, the relief valve is the key to protect the engine in an emergency. (Also called bypass valve)

Note: Regularly change the oil filter (the oil filter needs to be replaced every time the oil is changed) to avoid accelerated engine wear due to the overflow valve opening. Inferior and cheap machine filters do not have an overflow valve. In special cases, there is no supply of lubricating oil, which will lead to cranking, overhaul, and even scrapping.

2. On the problem of oil leakage after replacing the oil filter:

1. For the spin-on filter (iron shell), the rotation force is too large, exceeding the standard 20-60 Newtons (1 kg = 9.8), the correct installation is to install with the force of 2 kg hand, avoid installing with a wrench When the force is greater than 2.5 kg, the seal ring is easily deformed, protruding points are generated along the circumference, and under the impact of high-pressure airflow, a gap is generated and leaks.

2. The flat dirt contacted by the old oil filter is not cleaned.

3. When disassembling the old oil filter, the old seal was stuck on the filter seat due to the previous excessive rotation force, and the new oil filter leaked after being installed.

4. The lubrication system is seriously polluted. Heavy oil dirt blocks the main oil passage (or the sealant blocks the oil passage after overhaul), causing internal pressure and impacting the seal ring to cause oil leakage.

5. For the environmental protection filter (paper filter), the vast majority is that the seal ring in the guide rod is not removed, and a new seal ring is installed.

6. When replacing the environmental protection filter (paper filter), the new inner seal was not replaced.

7. The environmental protection filter element (paper filter element) still has excessive rotation force for the outer seal ring (large), causing serious deformation or hidden injury. It is impacted and leaks oil under pressure during work.

Post time: May-11-2020