Oil filter is the structure of engine oil lubrication circulation system, which can effectively reduce friction and wear. At the same time, heat generated by combustion and friction is transferred to cooling circuit to transport and remove wear particles. The function is to filter the metal debris in the engine and various impurities in the oil, to prevent the deterioration of the oil and to avoid wear and tear of the engine moving parts; in addition, when the oil filter is blocked, let the oil flow out properly to ensure the normal oil pressure. Oil filter generally requires 5000 kilometers to replace once, in order to achieve the best use effect.

1. Working principle of engine lubricating oil circulation system

In the process of engine operation, metal debris, dust, carbon deposit oxidized at high temperature and colloidal precipitate, water and so on are continuously mixed with lubricating oil. The function of oil filter is to filter out these mechanical impurities and colloids, keep the lubricating oil clean and extend its service life.

The oil filter shall have the characteristics of strong filtration capacity, low flow resistance and long service life.

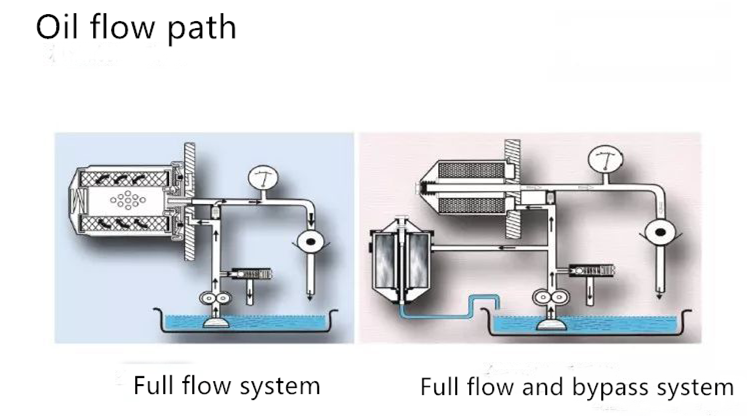

In general lubrication system, there are several filters with different filtering capacity – collectors, coarse filters and fine filters, which are connected in parallel or in series in the main oil passage respectively. (Full-flow filters are connected in series with main oil passages, and all lubricants are filtered by filters when the engine works; shunt filters are connected in parallel with them). The coarse filter is connected in series in the main oil pipeline and the fine filter is connected in parallel in the main oil pipeline.

2. Oil filter structure

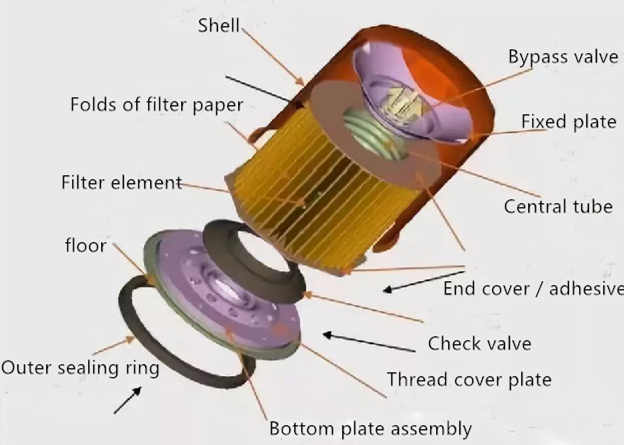

Filter paper: Oil filters require higher filter paper than air filters, mainly because the temperature of oil varies from 0 to 300 degrees. Under drastic temperature changes, the concentration of oil also changes correspondingly, which will affect the filtration flow of oil. High quality oil filter paper should be able to filter impurities under drastic temperature changes, while ensuring adequate flow.

Rubber Seal Ring: High quality oil filter seal ring is made of special rubber to ensure 100% oil leakage.

Return reflux valve: only the high quality oil filter is available. When the engine goes out, it prevents the oil filter from drying out; when the engine is re-ignited, it immediately generates pressure and supplies oil to lubricate the engine. (also known as “return valve”)

Overflow valve: only the high quality oil filter is available. When the external temperature drops to a certain value or when the oil filter exceeds its normal service life, the relief valve will be opened under special pressure, allowing the unfiltered oil to flow directly into the engine. In spite of this, impurities in the oil will enter the engine together, but the damage is much smaller than that caused by the absence of oil in the engine. Therefore, the relief valve is the key to protect the engine in emergency. (also known as bypass valve)

Post time: Nov-05-2018